Embedded Measurement and Control

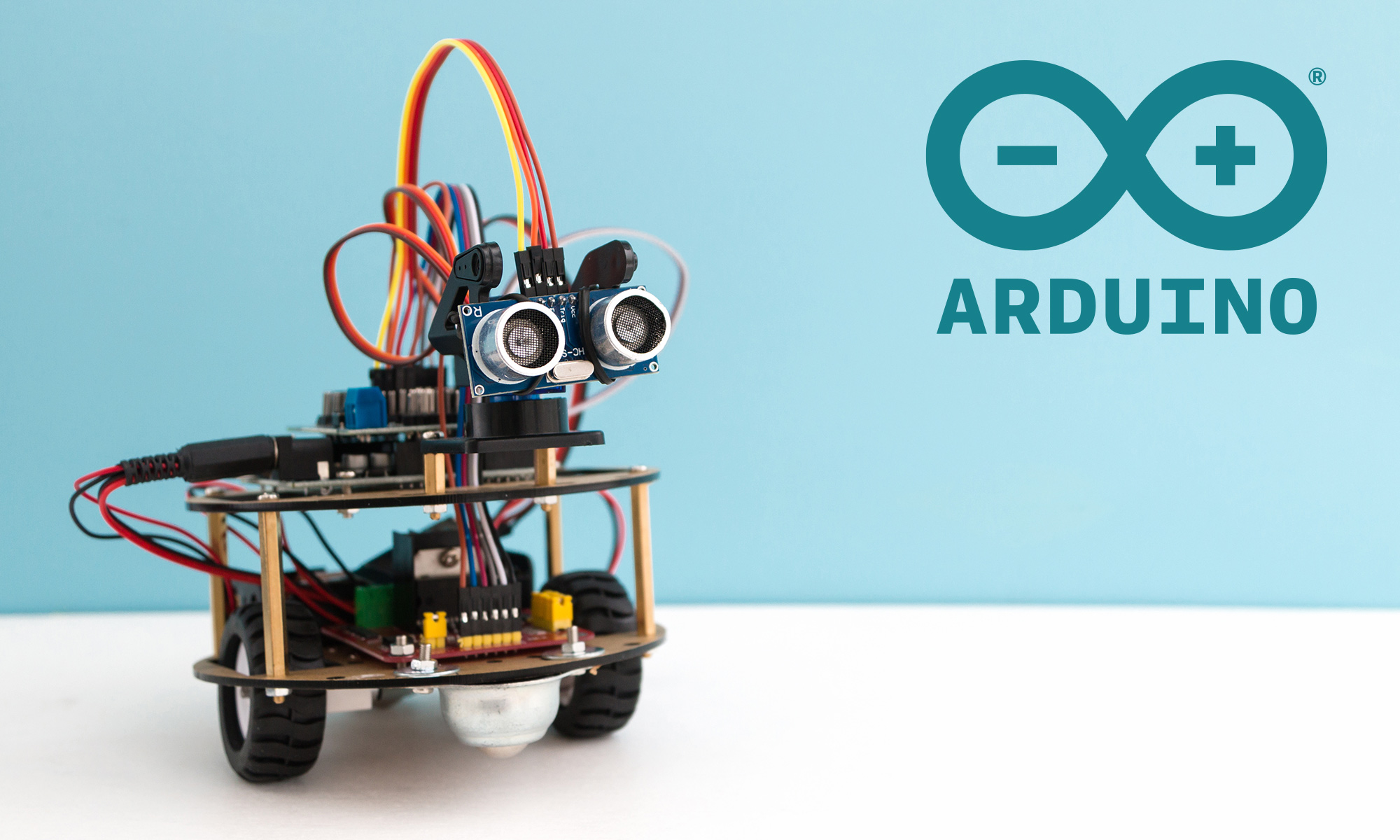

This course is an introduction to embedded development. The course focusses on developing embedded applications that use sensory input to drive external outputs.

This course starts by getting the student some experience in creating embedded applications that have a hardware and software component by using an Arduino and complementary peripherals.

When the students are practiced in creating these basic embedded applications, they start peeling away the abstraction layers that comes with using the Arduino software libraries. In doing so the student is able to understand the inner workings of a microcontroller and create performant embedded applications.

During the course, the students will be shown how to interface with different peripherals so they are able to implement when needed.

At the end of the course, Low Power Wide Area Networks (LPWAN) will be introduced, this technology has driven the rise of Internet of Things. We will use this technology to measure and control from a large distance.

This course starts by getting the student some experience in creating embedded applications that have a hardware and software component by using an Arduino and complementary peripherals.

When the students are practiced in creating these basic embedded applications, they start peeling away the abstraction layers that comes with using the Arduino software libraries. In doing so the student is able to understand the inner workings of a microcontroller and create performant embedded applications.

During the course, the students will be shown how to interface with different peripherals so they are able to implement when needed.

At the end of the course, Low Power Wide Area Networks (LPWAN) will be introduced, this technology has driven the rise of Internet of Things. We will use this technology to measure and control from a large distance.

Renewable Energy

This is a course on renewable energy.

The learning process includes theoretical learning, use of appropriate software tools and practical training using lab equipment.

Upon completion of the course, the students:

• Will have a good understanding of renewable energy systems, their components and interactions

• Will have knowledge of the regulations related to renewable energy, and they will be able to perform a basic techno-ecnomic analysis of renewable energy systems

• Will be able to perform an initial design of a renewable energy system

• Will have knowledge of appropriate software tools • Will get field experience for specific systems (hybrid systems including photovoltaics, wind turbines and energy storage)

The learning process includes theoretical learning, use of appropriate software tools and practical training using lab equipment.

Upon completion of the course, the students:

• Will have a good understanding of renewable energy systems, their components and interactions

• Will have knowledge of the regulations related to renewable energy, and they will be able to perform a basic techno-ecnomic analysis of renewable energy systems

• Will be able to perform an initial design of a renewable energy system

• Will have knowledge of appropriate software tools • Will get field experience for specific systems (hybrid systems including photovoltaics, wind turbines and energy storage)

Process Simulation & Control

In this course, the student will be able, starting form a practical/physical problem, to formulate a mathematical equivalent representation, by extracting the corresponding systems dynamics. By analysing the system’s behaviour, he will be able to select the desired response specifications and subsequently design the necessary closed loop system in order to achieve the design requirements. The student will be also

able using the appropriate software tools to simulate and test and evaluate/validate his design in a synthetic environment. Examples of mechanical, electrical, hydraulic and thermal systems will be utilized.

able using the appropriate software tools to simulate and test and evaluate/validate his design in a synthetic environment. Examples of mechanical, electrical, hydraulic and thermal systems will be utilized.

Sensor Technology

After completion of this course, students will be able to;

• Define and describe performance criteria for sensors

• Explain sensor classification and physical principles of the conversion of measured quantities into electric signal

• Define and interpret sensor technical specifications

• Describe sensor manufacturing technologies

• Apply international standards for particular sensors

• Analyse and interpret sensor output data

• Select a suitable sensor for given application to solve a problem

• Define and describe performance criteria for sensors

• Explain sensor classification and physical principles of the conversion of measured quantities into electric signal

• Define and interpret sensor technical specifications

• Describe sensor manufacturing technologies

• Apply international standards for particular sensors

• Analyse and interpret sensor output data

• Select a suitable sensor for given application to solve a problem

Advanced PLC & Motion Control

This course build on the fundamentals of the basic course and starts with the advanced TIA Portal instructions and solutions with focus on analogue signal processing and data-logging.

It continuous with an introduction into industrial network devices on Profibus & ProfiNET with focus on HMI, IO devices, drives and PLC-PLC communication. It ends with the engineering of software where students learn to apply software analyses such as GRAFCET and FLOWCHART.

The course continuous with hands-on workshops where students apply their knowledge to develop engineering skills. The student learns to select automation devices, to translate software analyses to software code, to troubleshoot PLC hardware and software problems in an environment that simulates the work field.

At the end of this course a student is able to analyze a complex automation problem and to work out a solution.

It continuous with an introduction into industrial network devices on Profibus & ProfiNET with focus on HMI, IO devices, drives and PLC-PLC communication. It ends with the engineering of software where students learn to apply software analyses such as GRAFCET and FLOWCHART.

The course continuous with hands-on workshops where students apply their knowledge to develop engineering skills. The student learns to select automation devices, to translate software analyses to software code, to troubleshoot PLC hardware and software problems in an environment that simulates the work field.

At the end of this course a student is able to analyze a complex automation problem and to work out a solution.

Basic PLC Programming

A programmable logic controller (PLC) is an industrial digital computer that has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, robotic devices, or any activity that requires high reliability, ease of programming, and process fault diagnosis.

PLCs can range from small modular devices with tens of inputs and outputs (I/O), in a housing integral with the processor, to large rack-mounted modular devices with thousands of I/O, and which are often networked to other PLC and HMI / SCADA systems.

In this course students will learn basic automation skills;

- To read and to understand engineering documents such as electrical drawings, datasheets, etc.

- To create electrical automation circuits

- To program and test automation software

PLCs can range from small modular devices with tens of inputs and outputs (I/O), in a housing integral with the processor, to large rack-mounted modular devices with thousands of I/O, and which are often networked to other PLC and HMI / SCADA systems.

In this course students will learn basic automation skills;

- To read and to understand engineering documents such as electrical drawings, datasheets, etc.

- To create electrical automation circuits

- To program and test automation software

Electrical Motors & Drivers

This course is the completion of electrical motors. The controlling of their speed, acceleration, decelaration, position, ….

In the theoretic course the students study how a motor can be controlled. In addition they learn the implications of changing parameters on an electrical motor.

During the hands-on-course, student apply their knowledge and learn, with the technical data, to change the settings of the controller. This has as a purpose to have the electrical motor completely under control.

At the end of the course the student must be able to connect and program a motor controller for basic settings.

In the theoretic course the students study how a motor can be controlled. In addition they learn the implications of changing parameters on an electrical motor.

During the hands-on-course, student apply their knowledge and learn, with the technical data, to change the settings of the controller. This has as a purpose to have the electrical motor completely under control.

At the end of the course the student must be able to connect and program a motor controller for basic settings.

Electrical Installations

During this course the student will learn to read an electrical plan and to build the electrical circuit as according to a plan.

In a second stage the student learns to complete an electrical plan before buiding it.

With the program Dialux the student learns to optimize lighting.

In a second stage the student learns to complete an electrical plan before buiding it.

With the program Dialux the student learns to optimize lighting.